Unique Pump System, Kailash Industrial Complex, Vikhroli West

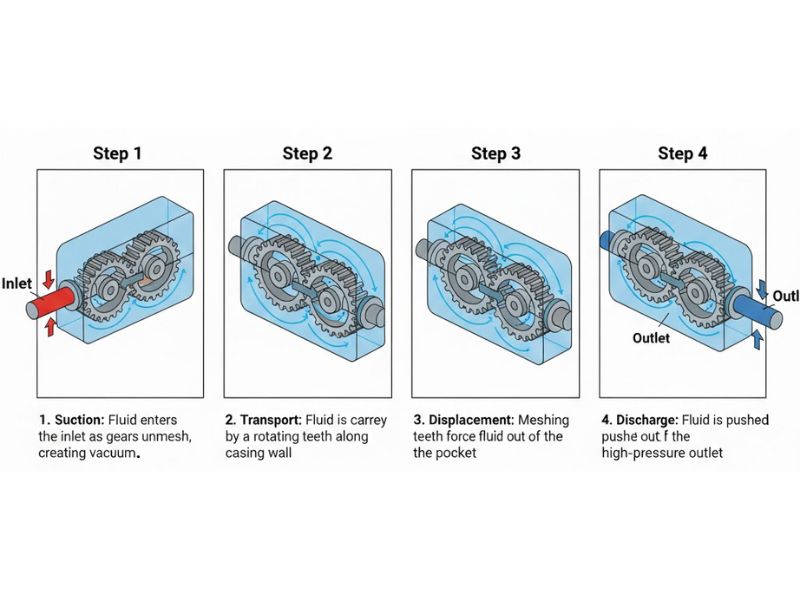

How a gear pump works is a common question for engineers, maintenance teams, students, and buyers who want a simple yet complete understanding of this widely used industrial pump. A gear pump works by trapping a fixed volume of fluid between rotating gear teeth and the pump casing, then mechanically moving that fluid from the inlet to the outlet at a controlled and continuous rate.

Because gear pumps use positive displacement, their flow remains consistent regardless of pressure variations, making them ideal for oils, chemicals, fuels, and viscous fluids.

Read More: What is Gear Pump?

The basic working principle of a gear pump is the same for all designs:

There is no fluid flow through the center of the gears, which prevents backflow and ensures efficiency.

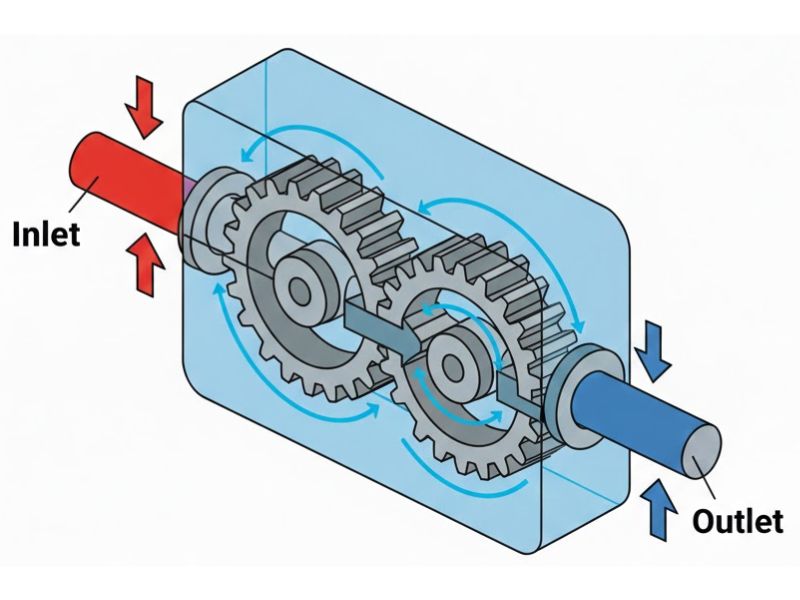

Understanding how an external gear pump works is simple because of its symmetrical design.

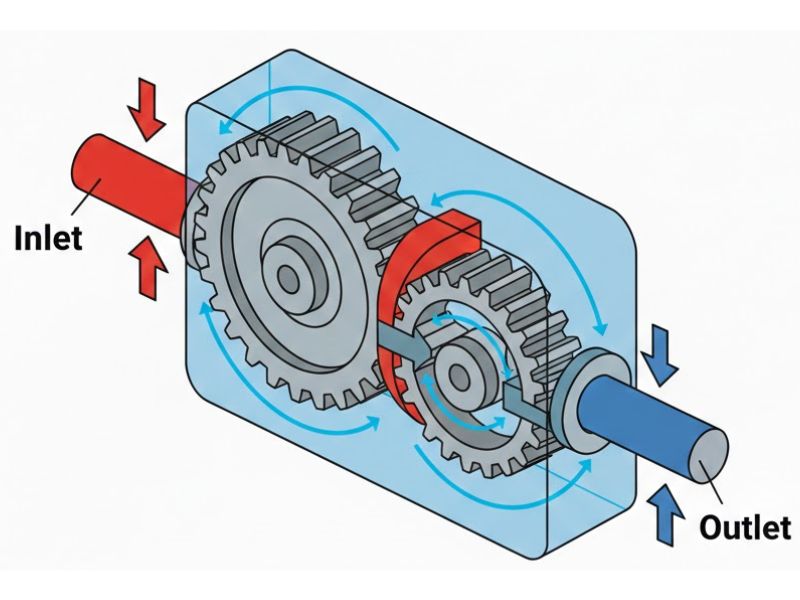

How the internal gear pump works differs slightly but follows the same positive displacement principle.

|

Feature |

External Gear Pump |

Internal Gear Pump |

|

Gear size |

Same size gears |

Different size gears |

|

Suction capability |

Moderate |

High |

|

Pressure handling |

High |

Medium |

|

Viscosity handling |

Low–medium |

Very high |

|

Noise level |

Higher |

Lower |

|

Flow smoothness |

Good |

Excellent |

Gear pumps deliver constant flow because:

This makes gear pumps ideal for metering, dosing, and blending applications.

Because of how gear pumps work, they are widely used in:

Yes, but gear pumps are better suited for viscous fluids. For water-like fluids, efficiency may reduce due to leakage.

No. Gear pumps rely on the pumped fluid for lubrication. Dry running can cause damage.

No. Flow remains constant; pressure only increases resistance.

No. Gear pumps provide smooth and nearly pulse-free flow.