Unique Pump System, Kailash Industrial Complex, Vikhroli West

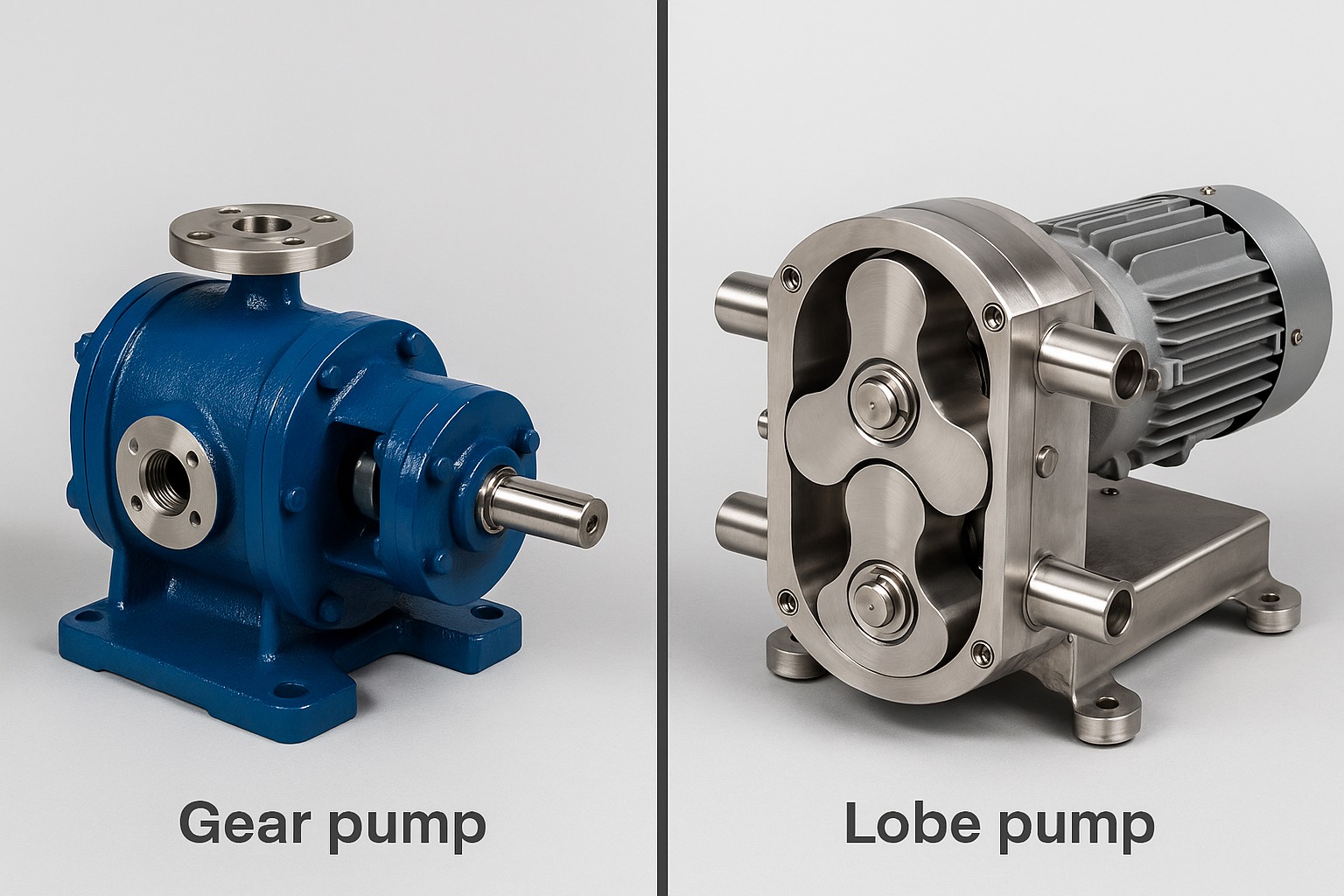

In fluid handling systems, choosing the right type of pump is critical to achieving performance, efficiency, and cost-effectiveness. Two of the most commonly used positive displacement pumps are Gear Pumps and Lobe Pumps. Each has its own advantages, ideal applications, and design features.

At Unique Pump System, we specialize in the design, manufacturing, and servicing of both Gear Pumps and Lobe Pumps. In this blog, we compare their applications, benefits, and usage to help you make the best decision for your operations.

| Application Area | Gear Pump | Lobe Pump |

|---|---|---|

| Viscous Fluids | Excellent | Very Good |

| High Pressure | Excellent | Moderate |

| Shear-Sensitive Fluids | Not Ideal | Excellent |

| Sanitary Applications | Not Recommended | Ideal (CIP/SIP ready) |

| Slurries or Solids | Limited | Excellent |

| Food/Pharma Industry | Rarely Used | Widely Used |

| Compact Installation | Ideal | Requires more space |

| Parameter | Gear Pump | Lobe Pump |

|---|---|---|

| Ease of Maintenance | Moderate | Easy |

| Seal Replacement | Periodic | Easy & accessible |

| Operational Lifespan | Long (with viscous fluids) | Long (with regular cleaning) |

| Downtime Risk | Low | Very Low |

Choose a Gear Pump if your application requires

At Unique Pump System, we don’t just sell pumps—we deliver tailored pumping solutions. Whether you're dealing with food-grade materials or industrial-grade oils, we have the right pump for your needs.