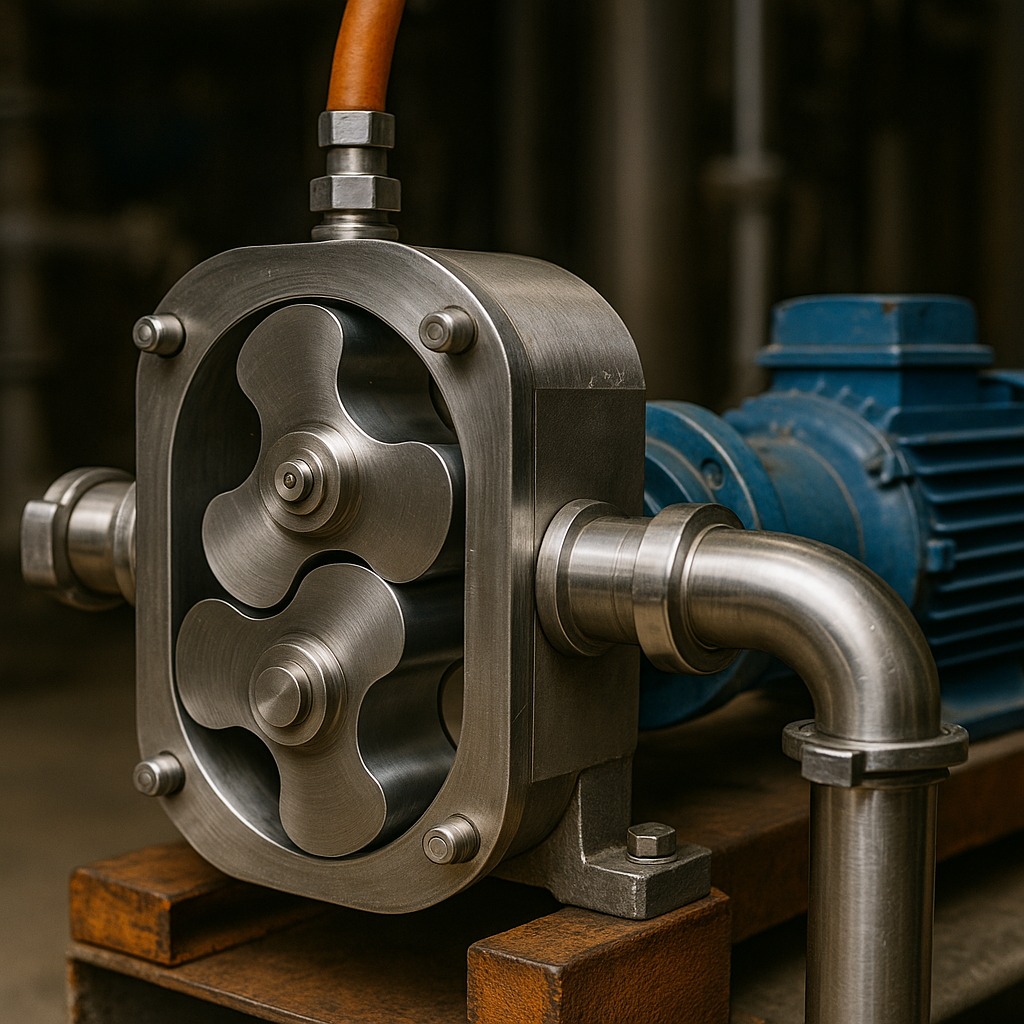

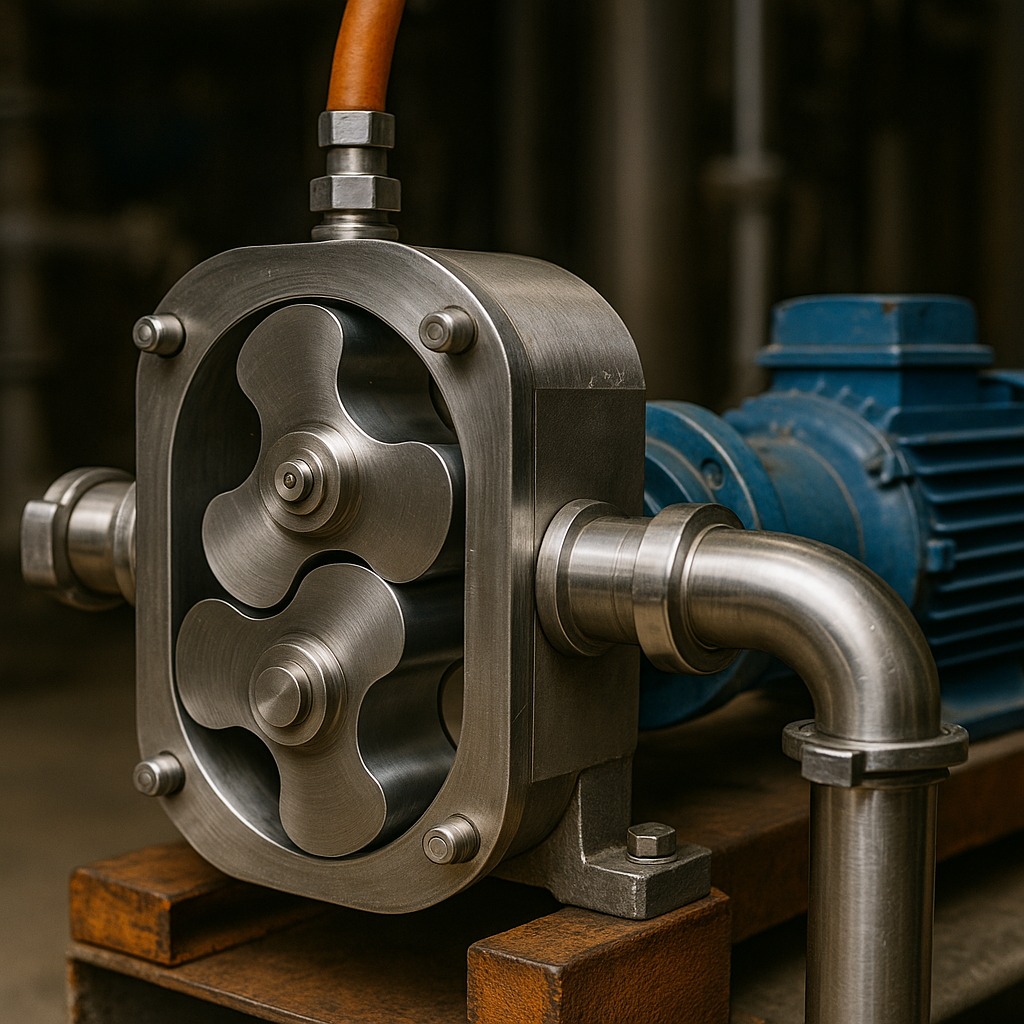

Lobe pumps are trusted across various industries for their efficiency in handling viscous

fluids, solids, and sanitary applications. Their reliable performance makes them ideal

for sectors such as food processing, pharmaceuticals, and chemicals. But like any

mechanical equipment, regular lobe pump maintenance is crucial for ensuring performance,

longevity, and safety.

At Unique Pump System, we specialize in manufacturing and servicing high-performance lobe

pumps and offer expert advice to help our clients maintain optimal operations.

Why Is Lobe Pump Maintenance Important?

Lobe pumps operate with precision, but over time, wear and fluid contamination can

reduce their efficiency. Preventive maintenance helps to

- Avoid unexpected breakdowns

- Maintain hygienic standards (especially in food/pharma)

- Improve energy efficiency

- Extend the lifespan of the pump

- Save costs on emergency repairs

Key Maintenance Tips for Lobe Pumps

- Inspect the Lobes Regularly :

The lobes are the heart of the pump. Regularly check them for

- Cracks, pitting, or wear

- Uneven contact or scoring

- Loose fittings

Worn lobes should be replaced promptly to avoid damage to the casing and

ensure consistent flow.

- Monitor Seal Integrity :

Mechanical seals and gaskets prevent leaks and contamination. Inspect them for

- Drips or residue buildup

- Misalignment

- Cracks or hardening

If seals are compromised, replace them immediately to avoid product loss and

equipment damage.

- Lubricate Bearings Properly :

Bearings must be well-lubricated for smooth rotation. Use

manufacturer-recommended lubricants and avoid over-lubrication, which can cause

overheating.

- Check for Abnormal Noise or Vibration :

Unusual sound or vibration during operation can indicate

- Misalignment

- Foreign particles in the pump

- Worn internal components

Stop the pump and investigate immediately to prevent escalati

- Flush and Clean After Use :

In sanitary applications,

cleaning the lobe pump after each batch is critical. Follow a Clean-In-Place

(CIP) protocol or manually flush with appropriate solvents to avoid residue

buildup or bacterial growth.

When Should You Service a Lobe Pump?

While maintenance frequency depends on the application and operating hours, we

recommend

| Component |

Inspection Interval |

| Lobes |

Every 3-6 months |

| Seals & Gaskets |

Every 3 months or sooner |

| Bearings |

Every 6 months |

| Alignment |

Annually |

Why Choose Unique Pump System for Lobe Pump Servicing?

As a leading manufacturer and service provider, Unique Pump System offers

- In-house and on-site pump servicing

- Genuine spare parts

- Custom AMCs (Annual Maintenance Contracts)

- Expert diagnostics and performance testing

- Industry-leading support

Conclusion

Proper lobe pump maintenance isn’t just a technical task—it’s a smart business

strategy. A well-maintained pump delivers better performance, reduces operational

risk, and supports compliance with hygiene and safety standards.

For professional servicing or maintenance consultation, contact us today at www.uniquepump.com or reach out to our

team for a free assessment.